Q & A about world famous Lion Numbering Machines

What is an Automatic Numbering Machine?

An Automatic Numbering machine is a stamp used to mark reference numbers, serial numbers, dates or letters. They are used on documents, tickets, cards, etc. in Legal, Medical and Business fields. On factory production sites, they can be used on product parts, plates, circuit boards, etc.

An Automatic Numbering Machine automatically advances to the next consecutive number after stamping the current number a specified amount of times.

This automatically advancing mechanism is also referred to as "Self-moving Numbering" or "Auto Advance Numbering". In the US, it’s also recognized as "Bates Numbering" or "Bates Stamping".

Though computers can be used to easily print serial numbers, Automatic Numbering Machines are still a big help when working on irregular size documents or in a limited space, and also come in very handy when there is no printer at the site. Automatic Numbering Machines are also commonly used in Banking, Hospitals, Legal Offices, Law Courts, and Government Agencies.

Why choose LION Numbering Machines?

LION Numbering Machines have 70 long years’ experience and a trustworthy name in the industry.

With a high reputation for quality, all Pro-Line Numbering Machines come with a 1 year limited warranty, so you can be certain of their long-lasting use.

Custom machines are available to your exact specifications, and we will perform repairs and overhauls when needed.

Please contact us with any requests or questions!

General Numbering Machine FAQ

Please start with "LION Numbering Machine Instruction" on our website to learn "How to Adjust Movement", "How to Set Numbering Wheels", "How to Drop Numbers Out of Print", "How to Ink Dry Pad / Re-Ink" and "How to Set Stamp Position".

Contact us with any further questions.

LION Automatic Numbering Machines automatically advance to the next consecutive number after a set amount of repeats. This pattern is called "movement."

There are 7 repeating patterns shown below:

Each numbering machine has either a 3-movement, 5-movement, or 7-movement setting, detailed below. For example, the LION C-71 has a 7-movement setting, so you can select the movement from 7 repeat patterns. A-31 has the 3-movement setting, so you can select from 3 repeat patterns. Please see the product detail page to learn which movements are available for each machine.

Yes. Set the movement indicator to 0 and the number will repeat until you change the setting.

Yes. Using the stylus, you can avoid printing unwanted numbers by dropping wheels. Please see "LION numbering Machine Instruction" on our website to learn "How to Drop Numbers Out of Print".

Please note that if the dropped wheel is part of the set of automatically advancing numbers, the wheel will be released and advanced to the next consecutive number when that position is reached. Also note that the last digit wheel can only be dropped on model B-33.

Yes. Using the stylus, you can drop the wheel where you would like to make a space. Please see "Lion Numbering Machine Instruction" on our website to learn "How to Drop Numbers Out of Print". Note that the dropped wheel will be released and automatically advanced to the next consecutive number when that position is reached.

If you want to make a space without dropping a wheel, you can order a custom stamp with a blank wheel or a gap between wheels.

Yes, A-01 is our lever action numbering machine. With each click of the lever, the number will advance.

The number will advance only when you click the lever, allowing you to repeat the same number as many times as you need before advancing to the next consecutive number. You can advance the last 5 digits/wheels with just a click on the lever.

Manually reset all wheels to 0 using the stylus that comes with the machine. Please see "LION Numbering Machine Instruction" on our website for more information.

To clean metal wheels, use thinner, nail polish remover or industrial gasoline (*most recommended) with a soft cloth. Do not use these directly on the wheels. Use a brush to clean between the wheels.

* Industrial gasoline is most recommended, since thinner and nail polish remover might cause discoloration or stickiness if spattered on the knob and sleeve.

To clean rubber wheels, use isopropyl alcohol and a soft cloth to wipe the surface of the wheels. To clean between the wheels, use a cotton swab soaked in isopropyl alcohol.

Caution: Do not rub with brush nor poke with any hard, pointed tools. Do NOT use thinner, nail polish remover or industrial gasoline (these are only good for metal wheels) as it might cause the rubber to detach from the wheel.

Though conditions will vary, a LION internal bench test demonstrated that LION Numbering Machines can stand up to one million stampings.

LION B-33 has the date on the first 6 digits (00.00.00) followed by the number on the last 4 digits. The last 4 digits are auto-advance. You can use this machine as a date stamper by dropping the last 4 wheels.

It will vary by machine. You can find the font size and the whole impression width of each numbering machine on our website product page.

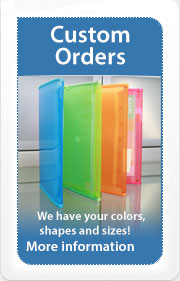

Yes, you can buy the pad holder clip (PFN-31) separately. Other spare pieces are available as well, so please contact us if you require any replacement parts.

Ink and dust will accumulate in the gears over time, and may cause the wheels to stick. Contact us for service if you see this problem.

To help avoid this issue, make sure with each stamp to push the handle all the way down and let it spring back all the way to the top.

We do our best to support our customers with repairs, so please contact us with specifics.

Numbering Machine Customization FAQ

Yes, though it will depend on the machine. Contact us for more information.

Yes, though it will depend on the machine. Contact us for more information.

Yes. Hooking a specialized "teeth" part under the digits you wish to advance (in this example, the first digits, "12345") will allow these digits to automatically advance instead of the last digits.

Unfortunately not. Auto-advance is only available up to 6 digits, due to the structure of the numbering gears.

Yes, machines can be customized to automatically advance fewer than 6 digits.

Yes. Depending on the width of the wheels, a specialized "teeth" part can be used to skip wheels. This may not be available in all cases, so contact us for more information.

LION C-75 comes with the letters A-K (excluding I) on the first wheel. Only A-H are available on the rubber wheel machine, MM-21. If you want any other letters or letters on any other wheels, the machine can be customized accordingly. However, this option may not be available in combination with other modifications. Contact us for more information.

Yes, the width can be customized by using special wheels in different widths or by adjusting the gaps in between the wheels. The machine requires a minimum width of 1mm (0.08") between characters, and the maximum impression width of the stamp is 45mm (1.8"). Contact us with any further questions.

On a standard 10 space wheel, the maximum character size is 6mm (0.236") in height.

If the auto-advance feature is not necessary, you can place five 8mm (0.314") characters per wheel.

A regular wheel is evenly divided by 10 spaces, allowing one space per character. To customize for larger fonts, the wheel can be divided into 5-9 spaces, and for smaller fonts or more characters, the wheel can be divided into 11-13 spaces. At 13 characters per wheel, the height of each character will be 4mm (0.157"), and at 12 characters per wheel, the height will be 5mm (0.197").

Please Note: The auto-advance and drop cipher features are only available on wheels with 10 spaces.

Below is one of the samples of a customized wheel. This particular sample uses one wide wheel divided by 5 spaces, and 2 lines (Confirmation, COM Center) are engraved on the fixed wide band wheel. The last 5 wheels (12-34) have 0 to 9 and advance automatically.

Yes. The combination of the wheel with 12 months (12 spaces) followed by the number wheels (10 spaces) is the most popular example. The numbers can advance automatically and the month wheel can be changed manually by using a stylus that comes in the package.

Our largest machine, A-31, has 13 wheels, but you can custom order a machine with up to 15 digits.

LMN-1 Numbering Machine Ink FAQ

Yes, of course. Please contact Customer Service to get the MSDS.

See "How to Ink Dry Pad / Re-Ink" on our website.

It dries quickly on copy paper, and takes approximately 30 min. to dry completely.

You should expect to get about 3,000 stamp impressions per fill. This will vary depending on how frequently you use the machine and how full and evenly you saturate the pad.

You should refill the ink whenever the impressions start to look dull or uneven.

On filed papers, a stamp impression will last about 15 years.

No, LION Numbering Machine Ink doesn’t contain any heavy metals or hazardous, restricted substances.

LMN-1 is an oil-based ink, and should not be used on glossy paper. To stamp on a non-porous surface, such as coated paper, we would recommend our LION Rubber Faced Wheel Automatic Numbering Machine MM-21 with LION Fast-Dry Ink MC-55.

LION Numbering Machine Ink LMN-1 is designed and developed to stamp on paper. If you need to stamp on something other than paper, please test on a sample first.

Yes, it does. However, please note that LMN-1 is only good for papers and cardboards, and not for non-porous surface such as plastics and metals.

Please Note: Parallel use of LMN-1 and MC-55 ink on the MM-21 Numbering Machine is not recommended.

If both inks need to be used on a single machine, please make sure to completely clean the ink left on the surface and in between the wheels with isopropyl alcohol and wipe off the stamp immediately before and after use. Any leftover ink residue might cause a problem.

Unfortunately, there is no solvent designed for removing LMN-1 ink stains from fabric. We recommend you wash the fabric with laundry detergent immediately.

Please note: Depending on the type of fabric and the severity of the stain, the ink may not wash out completely.

MC-55 Fast-Dry Numbering Machine Ink FAQ

Yes, of course. Please contact Customer Service to get the MSDS.

At normal temperatures, it takes about 3 seconds to dry on porous surfaces and 5 minutes on non-porous surfaces.

For best results, allow 48 hours for the ink to dry completely.

In most cases, a stamp impression in MC-55 ink will last for at least 15 years. Red and yellow inks might slowly fade over time and under exposure to sunlight or ultraviolet light, but the archival black ink will keep its original color.

Because our Fast-Dry Ink MC-55 is designed to dry with exposure to air, the ink pad will dry out if it remains exposed after use, and may need to be refilled before each use of the machine. We’d recommend you store the ink pad in an aluminum bag and seal it, to prevent exposure between each use.

No, it doesn’t. MC-55 complies with RoHS and REACH (SVHC) directives, which are the regulations on the use of certain hazardous substances in Europe, and are becoming the standard worldwide.

Yes, it is. Acid-free ink is ideal for archival storage as it won’t deteriorate the quality of the material.

Technically, yes. MC-55 ink can be used in metal wheel numbering machines, and won’t cause the machine’s mechanism to stick, the way that other pigment inks can.

However, we do not recommend using MC-55 ink with metal wheel numbering machines because the metal wheels won’t imprint well on the hard, non-porous surfaces that MC-55 ink is designed to work with. The reason we recommend using MC-55 ink with the MM-21 Numbering Machine is that the rubber wheels catch well on slick and hard surfaces such as metal and plastic. For softer surfaces, such as coated papers, the metal wheel numbering machines can work with MC-55 ink.

Yes, you can use MC-55 on stamp pads. However, please note that we would recommend that you use an ink pad with solvent-resistant case since MC-55 is a solvent based ink. Due to the quick drying nature of the ink, please make sure that the ink pad is covered tightly to avoid exposure to air when not in use.

Yes. Just make sure the stamp and cartridge/frame are solvent resistant, and the ink is tightly covered to avoid air exposure.

Unfortunately, there is no solvent designed specifically for removing Fast-Dry Ink stains from fabric. It will be very difficult to remove the stains completely.

No, it is not a permanent ink.

Numbering Machine Ink Pad FAQ

When the surface of the ink pad gets worn, you can turn it over and use the other side of the pad. Approximately 50,000 impressions are available per side, so a total of 100,000 stamps can be done per pad. When you notice the stamp impression isn’t as clean and clear, even after re-inking, please change the ink pad.

It’s made of highly absorbent wool.